High Precision Injection Molding Machines

conform to the Specification, Design, Manufacturing and Assembly of EUROMAP

MOLD CLAMPING FORCE

50T - 1080T

INJECTION VOLUME

45g - 6000g

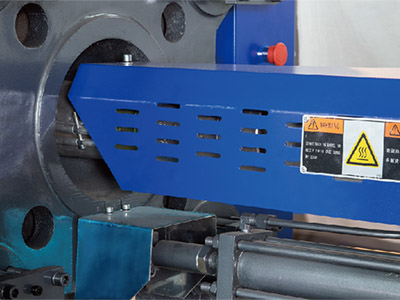

Mold Clamping

The inverted double-toggle three-rod five-hinge mold clamping structure with the optimized design features as the balanced movement, large mold moving stroke and fine rigidity. Four-step mold clamping pressure, speed and differential quick clamping device has has the multiple ejection modes and functions.

The machine uses the oil pressure bearing, with only the proportion of the proportion of the distribution of librication system, reliable lubrication and oil saving.

The use of self-run copper sleeve, the big column is not easy to scratch, permanent lubrication, make the molding area very clean.

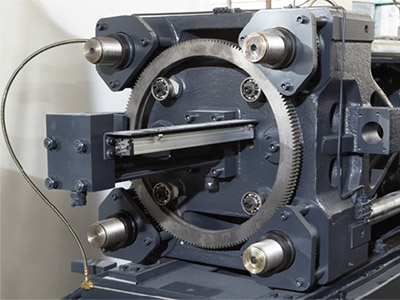

Injection

The paralleled double injection cylinders excute the even and balanced force to the screw in the injection process with large injection pressure.

The symmetrical double-cylinder injectionn shifting avoids the deformed cylinder, sealant leak due to uneven force to single cylinder. It brings about the more rational carrying capacity.

The compact multi-step injection speed, multi-step pressure control suit the multiple complex molding craft & technology to the plastic products.

Every model sets 3 to 4 different diameters of the superior alloy barrel screw with diameter-combining nitriding treatment. Meanwhile it is configurated with special screws for the engineering plastics with different characteristics in order to ensure the distinguished quality.

The integrated injection base is of the compact structure, light weight, strong rigidity, high reliability.

Different injection sets acceleration rod. It reduces resistance loss caused by large amount of oil return in the injection process and large amount of oil absorption in pre-plasticizing process. It thus increases the injection speed (partial speed).

Mold Adjusting

Horizontal double-toggle five-hinge hold-in design. It utilizes its own structural features to increase the opening strok and rod pitch etc.. Meanwhile it avoids hurting the mold (Small Machines) because of inclined mold board due to uneven force caused by dead weight of vertical parts.

Up/Down double-toggle five-hinge hold-in design (Medium and Big Machines).

High rigidity, high intensity box style integrated mold board analyzed by finite element reduces the accumulated error caused by the multiple processing and assembling. It thus increases the mold clamping accuracy.

It applies quantitative auntomatic lubricating system. It regularly of sequently executes quantitative oil supply to various lubricating points. It is effective and economical.

Low-pressure mold protection function prevents from mold damage.

Mold clamping structure has mechanical, electrical and hydraulic triple safety devices. It is used to ensure the staff security.

It is of high automatic mold adjusting precision. In renewing the mold, it can fulfill self-adjustment of mold clamping force through setting the parameters.

Quick mold clamping system applies oil pressure different circuit. It increases mold clamping speed, reduces the forming cycle.

High intensity rod plated with hard chrome matches with automatically lubricated copper wire. It is of smooth movement and long life.

Ejector pin applies position transducer control. It brings about the accurate forward and backward positioning.

Hydraulic

It applies the world's famous brand metering pump and control valve. It accurately controls the force and speed of hydraulic mechanism in an energy-saving way. It ensures the precise and reliable machine operation.

It applies the durable imported sealing parts.

The clear and concise oil pipe distribution reduces energy loss caused by oil circuit. It is convenient for repair and maintenance.

The unique oil-circuit design not only reduces the noise, but also increases rediating surface to the greates extent. It reduces oil temperature, usage amount of cooled water. It increases the service life of oil-circuit hydraulic sealing parts etc..

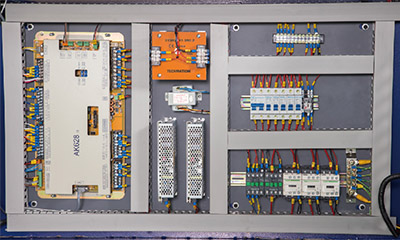

Control

New generation intellectual central controller with high precision and high stability Automatic trouble diagnose and alarm system.

It executes real-time temperature display functions.

Charging barrel temperature applies PID control mode.

The multiple modes of core pulling and ejector pin functions.

Production data storage, printing output function.

Display function of injection speed / pressure chart.

Automatic open/shut the machine or turn.

Mechanical arm interface loop.

Network monitor and control functions.

It applies large screen LED display screen. It support multiple nation's language system. It applies high speed and high precision German NOVO position sensor to ensure the position control accuracy.

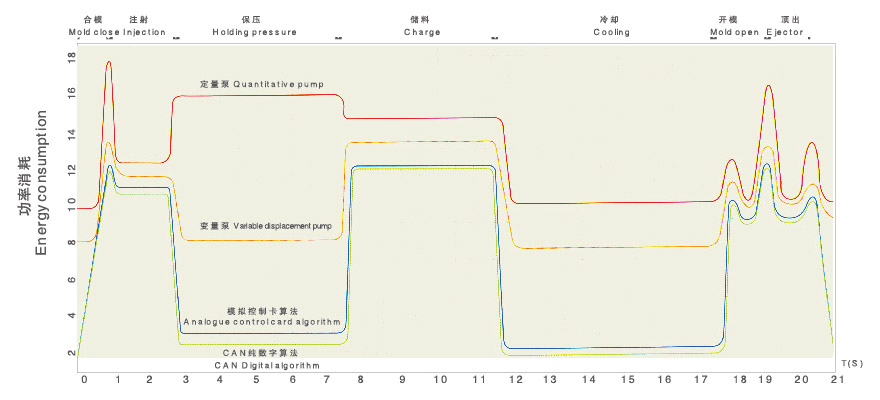

Comprehensive Performance

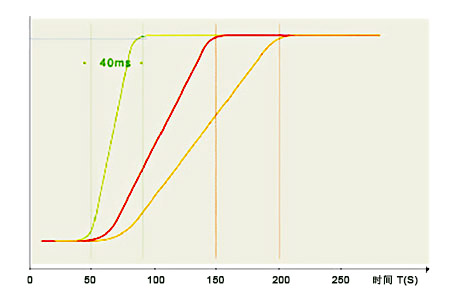

Response Characteristic Curves

J Series servo injection machine changes the output power along with the change of the workload, through all the stages in the injection process. J Series Injection Molding Machine always keeps at a low low level of energy consumption, so it can achieve a real energy-saving effect.

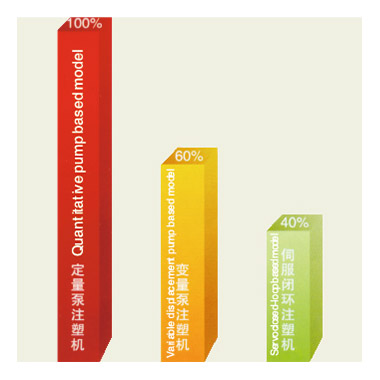

Energy-Saving Effect

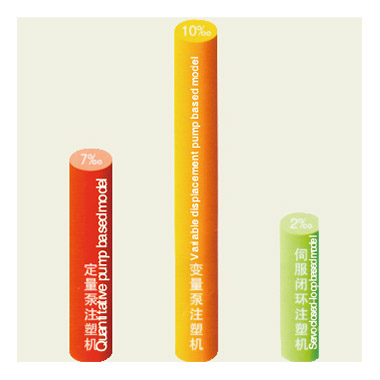

Accuracy

Technical Specification

DS-50T

DS-80T

DS-100T

DS-110T

DS-118T

DS-128T

DS-138T

DS-150T

DS-168T

DS-220T

DS-280T

DS-320T

DS-350T

DS-380T

DS-400T

DS-460T

DS-528T

DS-620T

DS-750T

DS-880T

DSX-1080T

| PARAMETER | UNIT | DS-138T | ||

|---|---|---|---|---|

| A | B | C | ||

| INJECTION UNIT | ||||

| Screw Diameter | mm | 38 | 42 | 45 |

| Screw L/D Ratio | L/D | 22.5 | 19.5 | 18.7 |

| Shot Size (Theoretical) | cm3 | 213 | 260 | 298 |

| Injection Weight | g | 191 | 221 | 253 |

| Injection Pressure | Mpa | 209 | 171 | 149 |

| Plasticizing Capacity | g/s | 17.8 | 19.6 | 22 |

| Screw Speed | rpm | 0-210 | ||

| CLAMPING UNIT | ||||

| Clamping Tonnage | KN | 1380 | ||

| Toggle Stroke | mm | 380 | ||

| Space between Tie Bars | mm | 420*420 | ||

| Max Mold Height | mm | 450 | ||

| Min Mold Height | mm | 150 | ||

| Ejecting Stroke | mm | 115 | ||

| Ejecting Tonnage | KN | 33 | ||

| Ejector Number | PC | 5 | ||

| OTHERS | ||||

| Max Pump Pressure | Mpa | 16 | ||

| Pump Motor Power | KW | 13 | ||

| Heater Power | KW | 9.75 | ||

| Machine Dimension (L*W*H) | m | 4.8*1.5*2 | ||

| Machine Weight (Approximate) | T | 4.3 | ||